22

09/2016

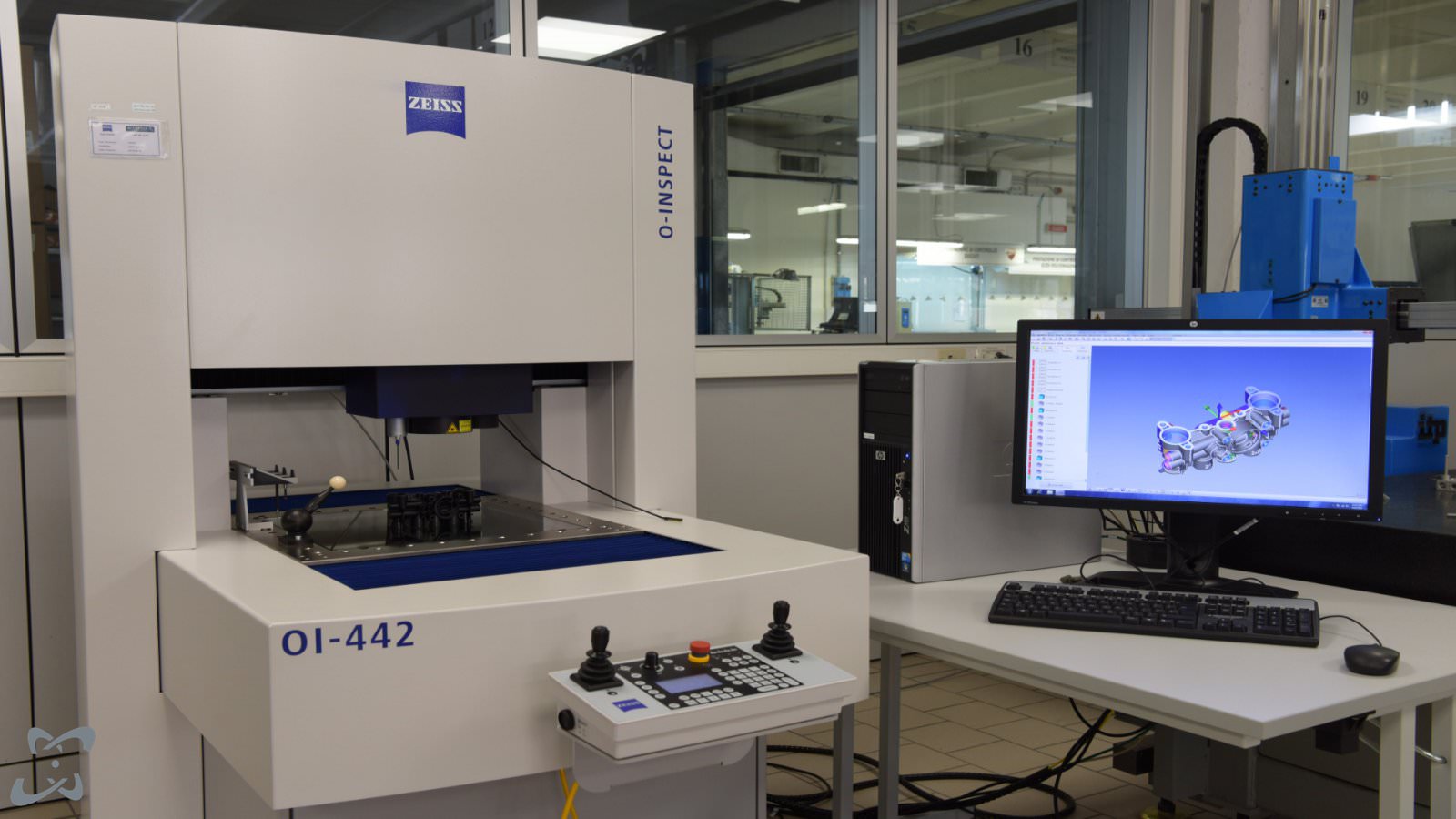

Techpol, with an eye to maintaining the highest technological and quality standards, has now introduced the Zeiss O INSPECT 442 optical machine in its Quality Laboratory, a high-tech machine with notable range of operation, considered to be the very top of the range when it comes to multi-sensor measuring machines.

The main strong point of the O-Inspect machine is its accuracy: high-precision measurements with uncertainty within the range of 2 – 3 microns.

The ZEISS O-INSPECT also makes it possible to measure every characterstic in optimum mode, either optically or by contact. It offers a 3D accuracy that is reliable, and conforms to ISO standards within a temperature range of 18 to 30°C. In addition, the CALYPSO software simplifies detection and identification of error causes.

Compared to standard lenses, this one provides a 4x larger visual field and a very good image definition, even in peripheral zones. The ZEISS also has a flexible, fast-acting and extremely precise contact sensor. This scanning sensor acquires a considerable number of points in a single sweep, so as to allow information statements of form and position.

It also allows scans with probing forces in the range of millinewtons, in areas where other multisensor measuring machines make it possible to measure just a single point with relatively high probing forces. This allows real 3D measurements of parts with thin walls.

The result is lower probing time with excellent accuracy.

Using a machine like the Zeiss O INSPECT 442 in our laboratory allows us to optimise the quality control of parts to achieve more detailed, precise and reliable results.

The aim, in line with our Quality Policy, is to continue to provide the highest levels of service for our customers and to deal with new challenges in the Motor Vehicle Industry.

Below is the declaration issued to Techpol by Dr. Arturo Cesa, Regional Sales Manager of Carl Zeiss Spa, and we would like to take the occasion to thank them officially and express our esteem for the company.

"Zeiss has had the great honour to provide Tech-pol Srl with the O INSPECT 442 high-tech machine with extensive working range”.

The Zeiss O-INSPECT is synonymous with optical and probe measurement using a single machine, with a single clamping process for the part, within a one-step measurement.

Great experience in coordinate and contact metrology together with recognised excellence when it comes to optics, both being the case for Carl Zeiss means that O-INSPECT has become a point of reference for multisensor measuring equipment.

The machine is equipped with the «Discovery» zoom lens by Carl Zeiss:

- 2-D optical sensor with image processing

- Carl Zeiss 12x zoom lens

- Extraordinary illumination using transmitted coaxial light and 16-segment multi-coloured ring lighting

Contact measurement is carried out using a VAST XXT sensor:

- Probe head with the possibility to measure in point/point mode and above all using continued scanning

- Support for automated probe change.

Two types of sensor: single software interpretation

- 3D measuring software with fully integrated optical and tactile function

- Possibility to import mathematical models.

The use of CAD models makes it possible to programme the machine quickly and easily. This inspection and testing method is currrently the most in demand in the major areas of the market. With O-Inspect it is now possible also to use CAD models for measurement, together with the optical sensor.

Lastly, the accuracy of the O-Inspect machine is of primary importance: high-precision measurements with uncertainty within a range of 2 – 3 microns”.