State-of-the-Art Tomographic Technology

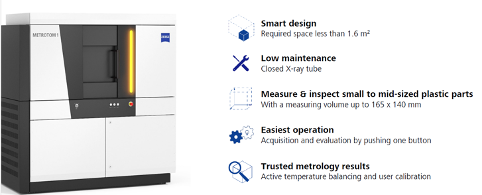

We are proud to announce a major step forward in enhancing our quality control and metrology department: we have recently acquired a ZEISS METROTOM 1 industrial CT scanner.

This cutting-edge industrial X-ray tomography solution allows us to deeply and accurately analyze both the external geometry and internal structures of complex components, without the need to destroy the part. With METROTOM 1, we can now perform complete 3D scans, detect internal defects (such as porosity, inclusions, or cracks), and compare real parts with original CAD models in a much shorter time and with micrometric precision.

Why did we choose the ZEISS METROTOM 1?

• ZEISS reliability: a synonym for metrological quality for decades

• High-resolution imaging: provides ultra-precise details, even on small parts

• Non-destructive analysis: complete internal inspection without cutting the sample

• Advanced software: intuitive data management with automated 3D analysis

With this new acquisition, we are now able to offer even more advanced inspection and control services to support our clients in the automotive, precision mechanics, and other sectors.

A step forward in quality control and verification

“With METROTOM 1, we can offer our clients a completely new level of inspection. We can detect internal flaws, measure complex geometries, and validate parts in a very short time. It is a strategic investment to strengthen our commitment to quality and innovation.”

— Eng. Matteo A. Viggiani, Quality Manager

The introduction of METROTOM 1 confirms our ongoing commitment to technological innovation, total quality, and continuous improvement of our processes.