Our in-house design department collaborates closely with customers throughout the development and engineering stages.

Its primary focus is on researching and developing technological solutions and innovations in injection moulding and mould mechanics. Additionally, it studies automation systems designed to optimize processes and enhance the production flow, ensuring efficiency from the initial plastic part design to the completion of the finished product.

We have implemented highly complex production processes, including Two-Component Moulding and Overmoulding, featuring:

- Metal and plastic inserts with dedicated assembly equipment

- Complex co-moulding of metal inserts

- Advanced plastic welding technologies, including vibration, ultrasound, hot blade, and infrared welding

- Control equipment for seals, tensile and compression loads, and measurement jigs

Our technical department utilizes cutting-edge software, including:

- CAD – Dassault CATIA V5-V4

- CAD – PTC CREO PRO 5

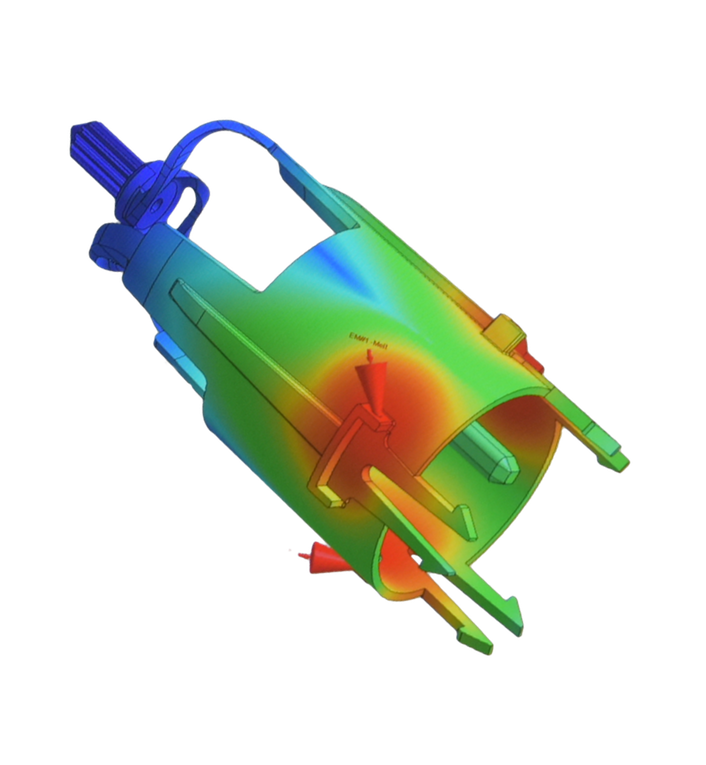

- CAE – MOLDEX 3D

- CAD – RHINO 3D

With these capabilities, we provide direct support to customers, contributing to the design and development of products seamlessly integrated into complex systems.