Techpol’s commitment to safety is embodied in a management system certified to ISO 45001:2018 and the adoption of the organizational model required by Legislative Decree 231/01, including whistleblowing procedures that ensure transparency and regulatory compliance. This solid regulatory foundation underpins cutting-edge structural and technological investments.

Structural interventions represent one of the most significant aspects of Techpol’s safety strategy. In 2024, Techpol completed a seismic vulnerability analysis followed by seismic reinforcement works that virtually eliminated earthquake-related risks at the plant. At the same time, the roof was upgraded with the installation of skylights equipped with fall-prevention nets and lifelines, significantly reducing the risk of falls from height while also improving indoor thermal comfort thanks to better temperature management.

Automation is a key component of Techpol’s safety philosophy. The automated logistics system, consisting of 2,200 shuttles operating along a 250-meter line, has completely replaced the manual handling of heavy loads — eliminating one of the main causes of workplace injuries in the manufacturing sector. This system not only reduces risks for workers but also helps maintain a cleaner, more orderly work environment, further reducing the risk of obstructions in production areas.

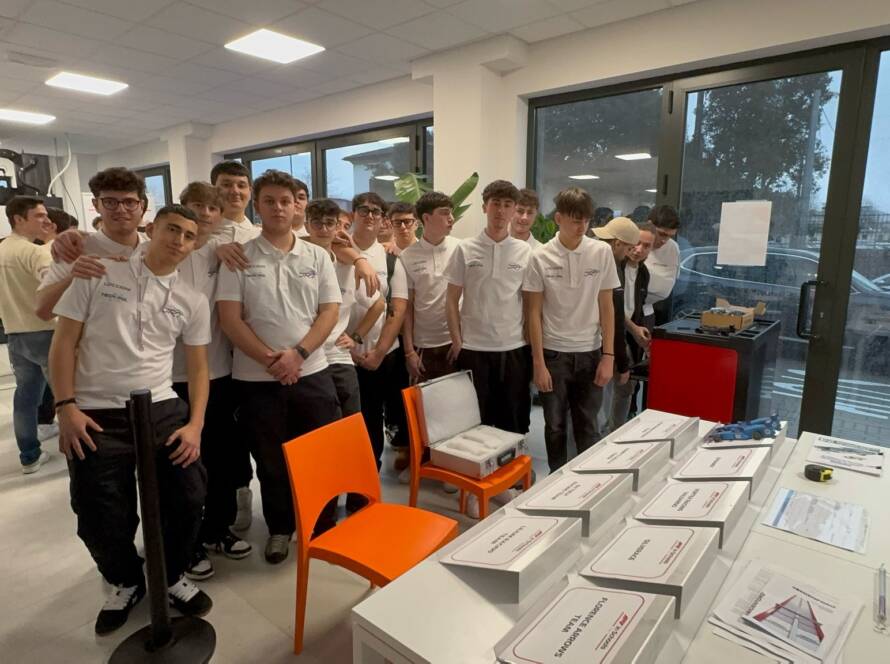

The culture of prevention is also fostered through high-level training initiatives. The event held on July 4, 2025, in Morro d’Alba and at the company’s premises, attended by about 30 occupational physicians from ANMA, turned Techpol into a case study for the prevention of biomechanical overload of the upper limbs. During this training day, occupational health professionals were able to directly observe the ergonomic solutions adopted by the company to mitigate the risks of repetitive movements, externally validating the effectiveness of the implemented practices.